Looking for Guaranteed biofouling control?

Our company helps power plants, desalination facilities, and industrial sites eliminate biofouling with smart, eco-friendly solutions

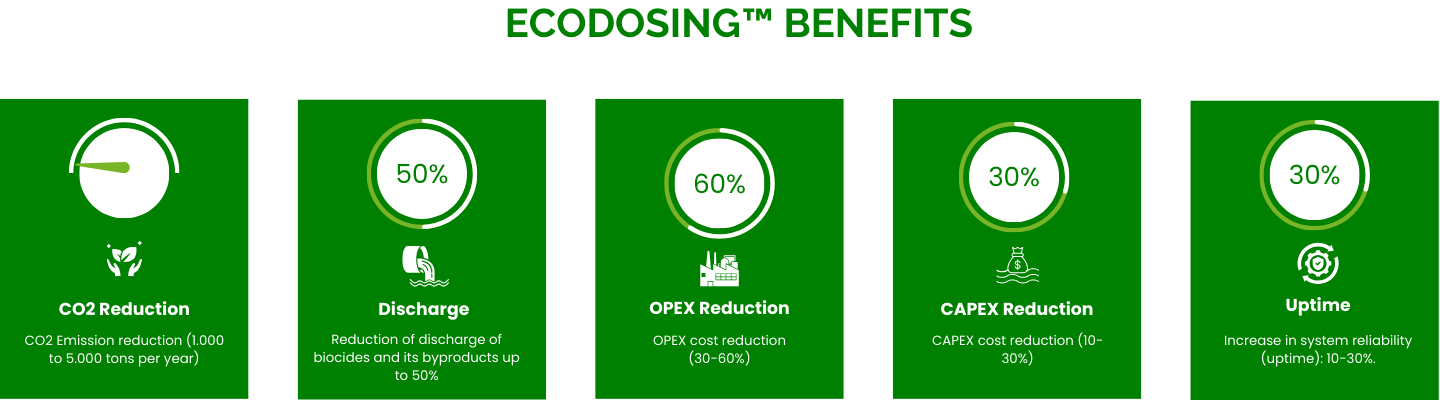

Solve Biofouling Challenges with Ecodosing™

Biofouling is one of the most common and costly challenges in industrial water systems. It slows down operations, increases energy use, raises maintenance costs, and can even pose environmental and compliance risks. Ecodosing™ offers a smarter way to manage it.

What Is Ecodosing™?

Ecodosing™ is applied for more than 25 years and a proven, sustainable biofouling control system that addresses the root causes of biofouling in industrial water systems. It’s recognised as the Best Available Technique (BAT) by the EU Integrated Pollution Prevention and Control (IPPC), making it a leader in the field.

This tailored dosing strategy ensures minimal use of biocides, effectively controlling biofouling while reducing your environmental impact.

Ecodosing™ goes beyond traditional biocide application. It’s a comprehensive biofouling management strategy designed to fit the unique conditions of your utility or facility. Instead of a one-size-fits-all approach, Ecodosing™ takes into account the specific characteristics of your system, ensuring safe, efficient, and environmentally compliant results.

Each implementation is tailored based on:

- The design and operation of your cooling or intake water system

- The types of local biofouling species present

- Water quality and seasonal variations

- System-specific restrictions and discharge permit requirements

How Ecodosing™ Works

- Customized Dosing Plans – We begin by assessing your system and developing a tailored dosing plan to ensure minimal biocide usage while effectively controlling biofouling.

- Advanced Monitoring – Our system includes real-time monitoring, ensuring precise chemical application and biofouling control without overuse of biocides.

- Controlled Cleaning of intake pipes – Ecodosing will remove gradually settled marine biofouling in intake pipes without overloading screening or stopping operations and use mechanical cleaning.

- Sustainable Biofouling Management – By continuously optimising dosing, we reduce your system’s reliance on harmful chemicals and lower the overall environmental impact of your operations.

Additional Solutions

In addition to biofouling control, we offer:

- Biocide Dosing System Design: From initial concept to installation, we design efficient dosing systems tailored to your needs.

- Expert Chemical Selection: We help you choose the right biofouling control chemicals based on local conditions.

- Environmental Impact Assessment: We assess the potential impacts of biocide use, including possible byproducts like trihalomethanes (THMs).

Proven Success at SWRO Desalination Plants

Ecodosing™ has already helped clients across the globe reduce operational costs and improve system reliability. At several SWRO desalination plants, Ecodosing™ led to biofouling free intake systems and extended the lifespan of reverse osmosis membranes. In addition, Ecodosing™ resulted in a gradual cleaning of intake pipes without mechanical interventions and was able to regain head loss close to design specifications. This success, among many others, demonstrates how Ecodosing™ is making a tangible impact on industrial water systems worldwide (Ecodosing Case Studies).